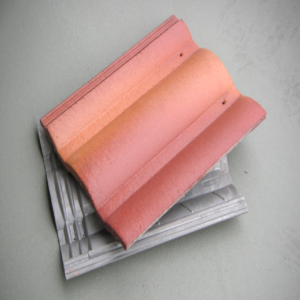

The vacuum brick-making machine is a piece of advanced professional equipment for making bricks and tiles, which can make bricks and tiles without firing. The vacuum tile machine produces tiles through vibration forming and hydraulic pressure. The natural maintenance process of vacuum tile machine products also has some aspects that need attention.

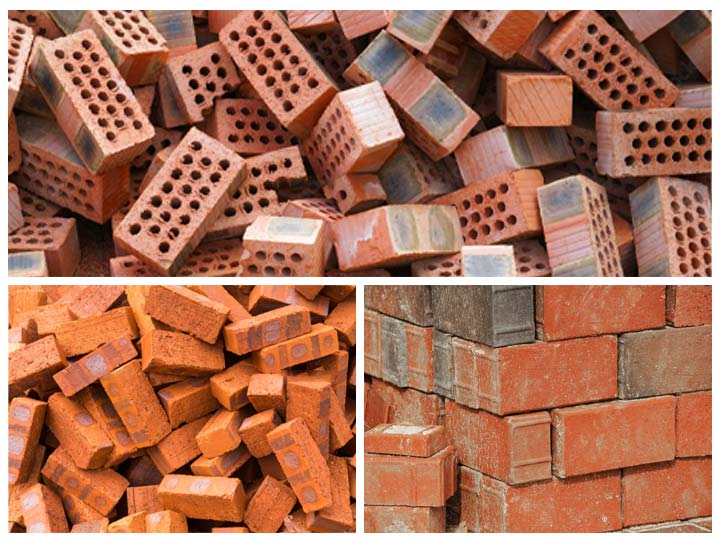

Usually, the brick-making plant has a lot of space in order to make enough tiles and bricks. Therefore, it is necessary to ensure that the site area is large enough to place a large number of finished products.

Maintaining the average curing temperature at 20 degrees Celsius is conducive to the molding of vacuum brick and tile products. The bricks and tiles just produced are low in strength and easy to break. Therefore, the ground surface of the site needs to be maintained to prevent the flatness of the bricks from being affected and damage to the bricks.

The place where the bricks and tiles should be placed should not be too high, as too high will cause the center of gravity to be unstable, and the weight of its own may crush the bricks that have not been cured at the bottom.

When curing the vacuum brick and tile machine products, it is used to prevent the cracks in the bricks caused by the rapid evaporation of water. The finished product must be sprinkled with water twice a day. When the temperature is very low in winter, insulation measures should be taken.