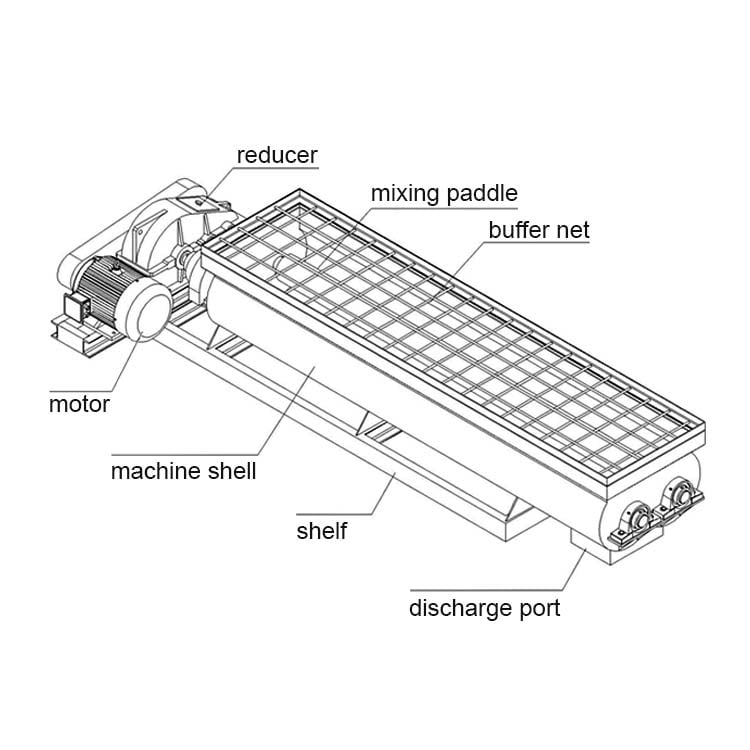

Introduction of double-shaft mixer

The double shaft mixer uses two mixing shafts, and the raw materials are stirred in the direction of the screw. The mixing time can be controlled, and the feed opening can also be opened for continuous feeding and stirring. It is suitable for mixing wet soil and wet mud, mixing a dry powder with water, mixing coal slime, etc.

Working principle of the double-shaft Mixer

The working principle of the double-shaft mixer is that the transmission device drives the two-blade shafts with mixing blades to rotate synchronously. When the material enters the tank from the feeding port, the water spray device immediately sprays water to make the material change from dry to wet; At the same time humidification, the wet material is continuously stirred and mixed with each other under the action of the spiral stirring blade and moves toward the discharge port, and then the material falls from the discharge port.

Advantages of clay mixer

- The mixing and conveying process of the enclosed mixer is carried out in a closed space with no dust leakage, It’s clean and environmentally friendly.

- The machine structure is compact, it occupied a small space, and the transmission is stable.

- The machine integrates mixing, humidification and conveying, with good mixing uniformity, high production efficiency and low noise during work.

- The shaft end adopts labyrinth type and packing type combined sealing, which has double sealing effect and good sealing effect.

- The mixing blades are made of wear-resistant materials and have been treated with a special surface to have high wear resistance and long use time.

Three different kinds of mixer

Maintenance considerations of double shaft mixer

- Pay attention to check whether the components are normal before running

- Since the bearing bears the full load of the machine, it is necessary to always pay attention to the lubrication of the bearing, add oil in time, and pay attention to the cleaning of the oil and the sealing of the bearing.

- Before using the new machine, it is necessary to refuel the reducer. When the machine is running in an empty test, there is no loud abnormal noise before it can be used normally.

- When the bearing oil temperature rises, immediately stop the machine and check the cause.

- Frequently check the degree of wear of vulnerable parts, and replace new parts in time.

Parameters of double shaft mixer

| type | power (kw) | chamber size (mm) |

| 500 | 5.5 | 1700*500*300 |

| 600 | 7.5-11 | 1800*500*600 |