A tile press machine is a machine used to produce clay tiles. If you want to develop well in the industry, you must understand the machines and the characteristics of clay tiles. Only in this way can we give full play to the advantages of the machine and purchase machines based on our own development status. If you want to buy a tile press, you can consider the following aspects.

Types of tile press

There are different types of tile presses. Our company has two different tile presses. The first is a manual tile press. The manual tile press is a machine that presses tiles manually. The other is a hydraulic tile press, which uses hydraulic power. Eliminates the workload of manual pressing.

How to choose a tile press machine

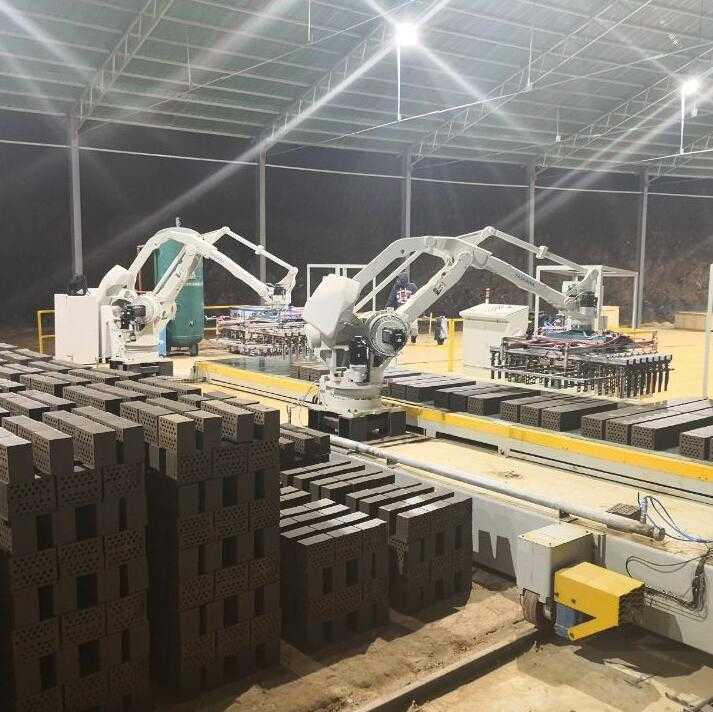

Yield considerations

If you want to purchase a tile press machine, you first need to consider how much you need to produce each day. If you are a small-volume manufacturer, you can use manual pressing. If you want to produce clay tiles with high output, you need to purchase clay with a high degree of automation. Tiles, such as hydraulic tile presses. The production efficiency is higher.

Human considerations

Labor is also an important part of the production. The manual pressing machine may require manual pressing. The higher the degree of automation, the higher the production efficiency, and the less labor required.

Types of tiles produced considerations

Generally, the type of tile produced is determined by the raw materials used in the mixture. The shape and pattern of the tile produced are determined by the mold of the tile press, so the two types of tile press machines can produce different types of clay tiles.

Price considerations

Of course, machines with a high degree of automation have advantages in all aspects, but the price of hydraulic presses is higher than that of manual tile press machines. For producers who have just entered this industry, they cannot afford to use manual presses. Tile machines are upgrading their machines when they want to expand the industry.