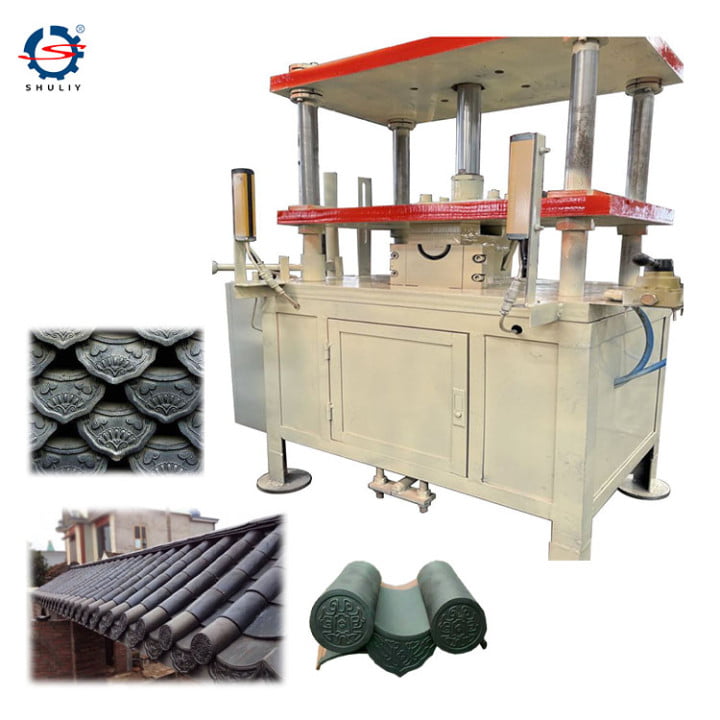

The hydraulic clay roof tile press machine is a machine used to make clay tiles. The hydraulic tile press body replaces the traditional tile pressing method and adopts a hydraulic system to make the tile manufacturing industry more efficient. The production efficiency is greatly improved. This product is widely used in the building brick and tile industry. We also have a manual tile press, which is suitable for small manufacturers and can choose independently.

Types of tiles that the hydraulic clay roof tile press machine can process

There are many types of tiles, such as clay tiles, glazed tiles, Roman tiles, Venetian tiles, and other types of tiles. Tile presses are all suitable, and the most common is to produce clay tiles, because the raw materials of clay tiles are simple and the finished products are low, and they are also very popular.

How does the tile press produce different types of tiles?

The main function of the tile press is to generate a certain pressure on the raw materials through the hydraulic system. If you want to produce different types of tiles, it mainly depends on the selection of models. Through different models, different clay tiles can be produced. In addition, if you want to produce patterned tiles, you need to install molds with corresponding patterns.

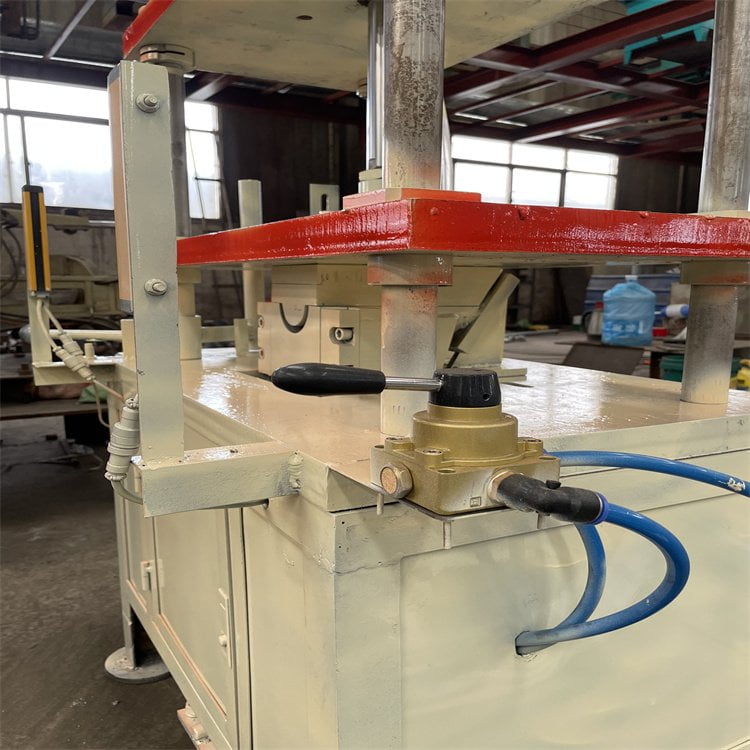

The structure of the hydraulic clay roof tile press machine

The hydraulic tile press is mainly composed of the main engine, hydraulic transmission system, and electrical control system. The machine adopts hydraulic pressure as power, which changes the traditional hand pressing method, and the speed is more stable and even. The machine adopts a special oil return setting to improve the safety factor.

Parameters of the hydraulic clay roof tile press machine

Pressure:15t

Capacity:1000pcs/shift

Size and shape can be customized

Equipped with 70L air compressor

Dimension:1.2*1.2*2.3m

Weight:600kg

Advantages of hydraulic clay roof tile press machine

1. One machine with multiple functions can produce a variety of products by changing the mold, and it can also produce different types of tiles.

2. It adopts pc, electromechanical, hydraulic, and gas-integrated control, and adopts a fully automatic control system. Save time, effort, and worry.

3. The equipment investment is small, the output is high, the speed is fast, and the funds can be returned quickly.

Precautions for using hydraulic tile press

1. The tile press should check whether the connections everywhere are firm and whether the installed nuts are tightened

2. If enough lubricating oil should be added to the case, first run it idling to see if it can work normally.

3. The clay roof tile press machine has different molds, and the power supply needs to be cut off when changing the molds.

4. The hydraulic roof tile press machine needs to add a cooling device in time, which can reduce the temperature and extend the service life of the machine.