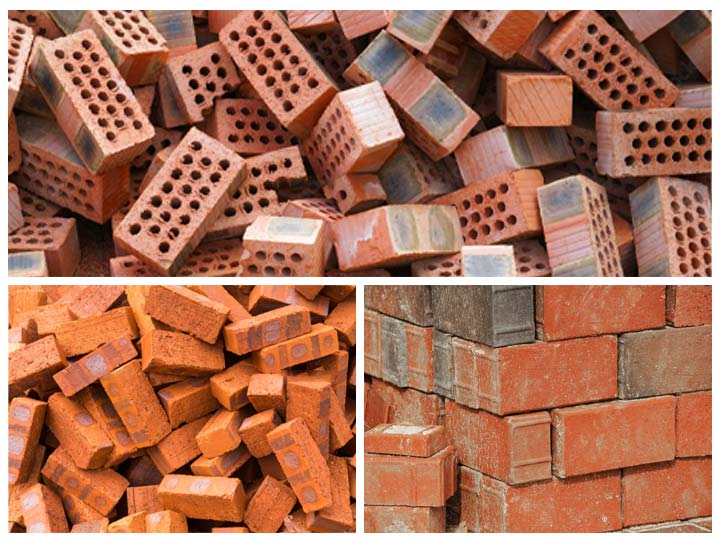

Brick tile-making machines have been widely used in many industries, which are closely related to their performance advantages. Clay bricks can greatly reduce the air content in artificial mud. The distribution of mud with it will be very uniform.

Although the machine is more time-saving and labor-saving than manual work, the operation specifications should also be paid attention to during the use of the clay drill to ensure safe use and prevent accidents.

First of all, clean the ground before using the brick tile-making machine to ensure that there is no debris or metal mixed into the soil, and check whether the clay drill has external failures to ensure the smooth progress of the clay practice.

Then, turn on the vacuum machine first, and then turn on the clay machine according to the startup procedure. When the mud training machine is working, pay special attention not to extend your hands or shovel into the mud feeding port to ensure personal safety and machine safety.

Subsequently, when the brick tile-making machine is shut down, effective maintenance measures must be taken at all entrances and exits to ensure that there is no agglomeration in the machine, and all power supplies of the machine should be cut off to avoid safety accidents. After the shutdown, clean up the debris in the mud practice ground to keep the ground clean and tidy.