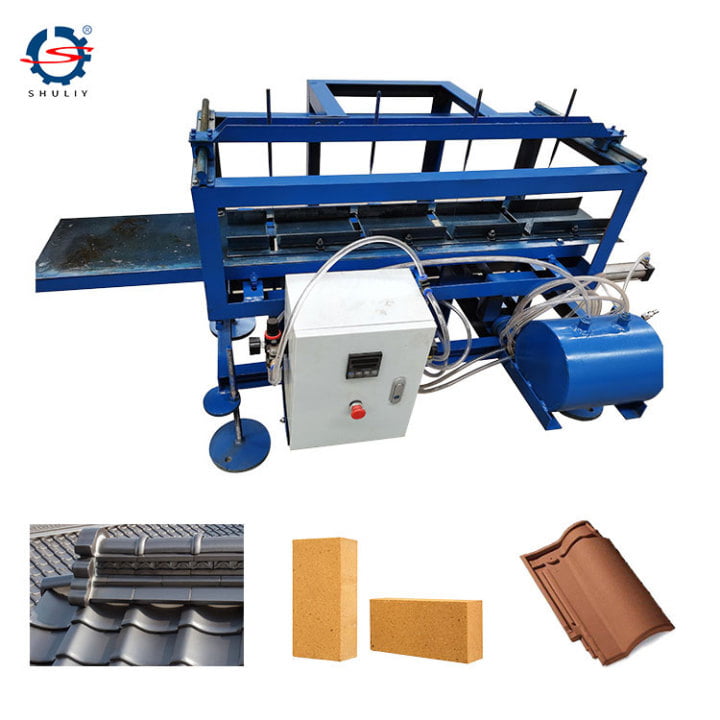

The clay brick cutting machine is the equipment used to produce bricks and tiles. The wire cut clay tiles machine can be used to process clay tiles and bricks. The machine can produce bricks or semi-circular tiles. We also have a whole clay tile production line, which can make clay into bricks and tiles for construction.

What kind of materials can be used to make bricks?

There are many raw materials used to produce bricks, such as clay, shale, coal gangue, industrial slag, and oil shale. Clay is a plastic aluminosilicate with very small particles. In addition to aluminum, clay also contains a small amount of magnesium, iron, sodium, potassium, and calcium, which is an important mineral raw material. Clay can remain undeformed for a long time after being molded after being wet. This also ensures that it will not be deformed during drying, which is very suitable for processing into building materials.

The structure of the clay brick cutting machine

The vacuum tile cutting machine is mainly composed of a reducer, a spindle, a feeding cylinder, a vacuum cylinder, a reamer, a sealed box, a frame, and a machine head; it has multiple functions and a variety of products. It can produce more than 80 varieties by changing the mold. 100 Various specifications. The size of clay bricks can be customized according to requirements, and the size is adjustable.

How to use a clay brick cutting machine?

Need to manually turn on the work switch to start the hydraulic system. The clay tile machine needs to be placed behind the clay brick forming machine. After the clay is crushed and shaped, the clay tile machine is used to cut the clay bricks into bricks of the same size.

Features of wire cut clay tiles machine

A Clay brick cutting machine is the special equipment for processing clay bricks. The machine is not only powerful, but also labor-saving, cost-saving, and high-efficiency. It can cut tiles of various specifications, which greatly reduces the benefits of manpower cutting. It is convenient, tidy, and beautiful. The most ideal supporting equipment. It solves the shortcomings of manual blank cutting, greatly improves the cutting speed, and is a very practical blank-cutting tool.

Clay brick-cutting machine parameters

Size: 2.4*1.2*1.2m

Weight: 150-200kg

Configuration: equipped with a 3-kilowatt air compressor

How much coal is needed to make bricks

For clay bricks of 1053 inches, the total amount of coal required for firing each brick is about 200-250 grams (including adding coal to the raw bricks). After calculation, it takes 20-25 tons of coal to burn 100,000 bricks, 40-45 tons of coal to burn 200,000 bricks, and 10-12 tons of coal to burn 50,000 bricks. The raw materials needed to burn bricks can also use biomass briquette (sawdust, rice husk, straw, etc.) as fuel.

Application of clay bricks

Clay bricks are mainly used as raw materials for construction, which can be used to build houses and pave roads, as raw materials for decorating gardens, and clay tiles are mainly used as building materials for the roof of houses. Clay bricks are widely welcomed because of their low price, simple raw materials, and the characteristics of fire resistance, heat insulation, and moisture absorption.