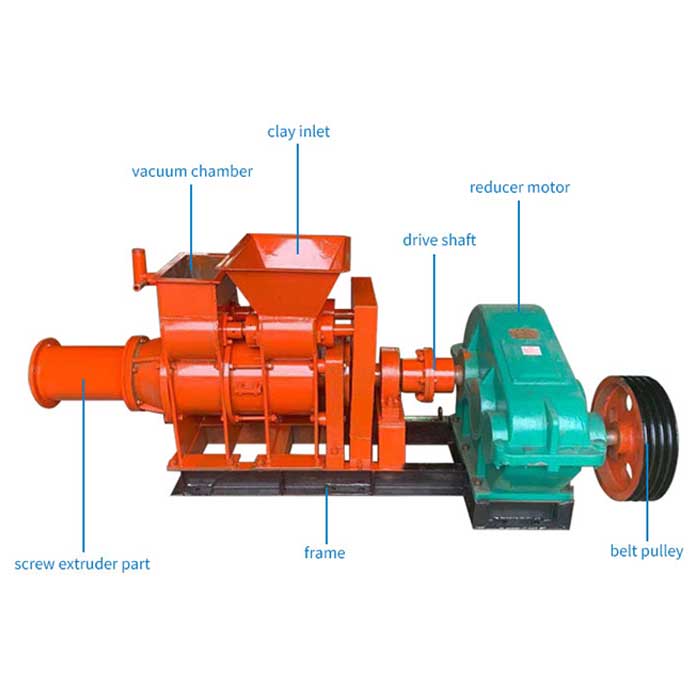

A De-airing pug mill is a machine used in ceramics, mining and other industries to practice clay. It is also called clay brick making machine. De-airing pug mill is mainly composed of transmission parts, speed regulation, feeding, and vacuum extrusion. The vacuum clay mixer is not only simple in structure but also practical in practice. It is also more convenient in the application process.

Introduction of de-airing pug mill

Clay brick machine, also known as pottery mud extruder and clay brick machine, is used for refining and washing mud. It is used for refining ceramics, electric porcelain mud and extruding tiles. It is suitable for extruding water content of 19%-23% of mud. It is widely used in household ceramics, electric porcelain, building materials, tile making, refractory materials, chemical materials and other industries. The clay brick extruding machine can produce bricks and tiles. The quality of the clay brick extruding machine is reliable and durable.

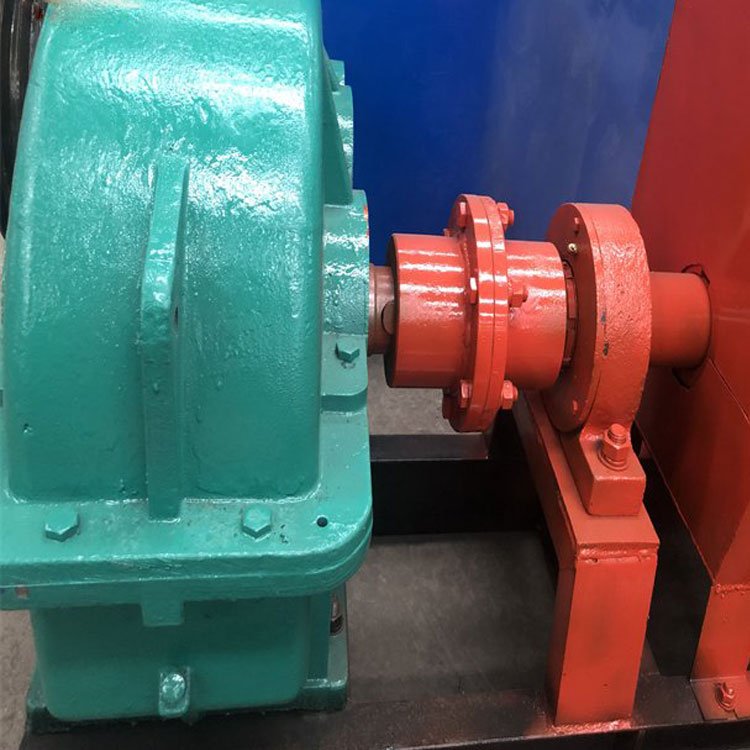

Structures of clay brick making machine

The soil brick making machine is mainly composed of a reducer, vacuum chamber, electric motor or diesel engine and molds. The vacuum pump alone requires a motor or diesel engine. The die is usually round, square or flat. Of course, it also accepts customization, such as flower shape. Customers only need to send us the sample drawing.

How does a de-airing pug mill work?

The feeding of the clay brick extruding machine adopts gear transmission, which has high speed and high efficiency, which solves the problem of difficult feeding of the mud mixer. The machine adopts dual-axis feeding and stirring, and uses a suspended rotating trowel to fully rotate the raw materials in the mud tank and then squeeze them out, reducing the problems of large particle size, air bubbles, and low efficiency during labor and mud.

Main features of clay brick making machine

- The clay brick extruding machine is small in size, light in weight, easy to transport, and occupies a small area.

- The products produced are of various shapes and sizes, and can be customized. By choosing the right molds, products of different varieties and specifications can be produced.

- The de-airing pug mill consumes less power, saves energy, and helps reduce production costs.

- The vacuum mud mill can reduce labor, reduce labor intensity, improve labor efficiency, and reduce production costs.

- The product made by the vacuum mud mill has high hardness and a smooth surface.

Precautions when using a clay brick machine

Soil brick making machines have been widely used in many industries, which are closely related to their performance advantages. Clay bricks can greatly reduce the air content in artificial mud. The distribution of mud with it will be very uniform.

Although the clay brick making machine is more time-saving and labor-saving than manual work, the operation specifications should also be paid attention to during the use of the clay drill to ensure safe use and prevent accidents.

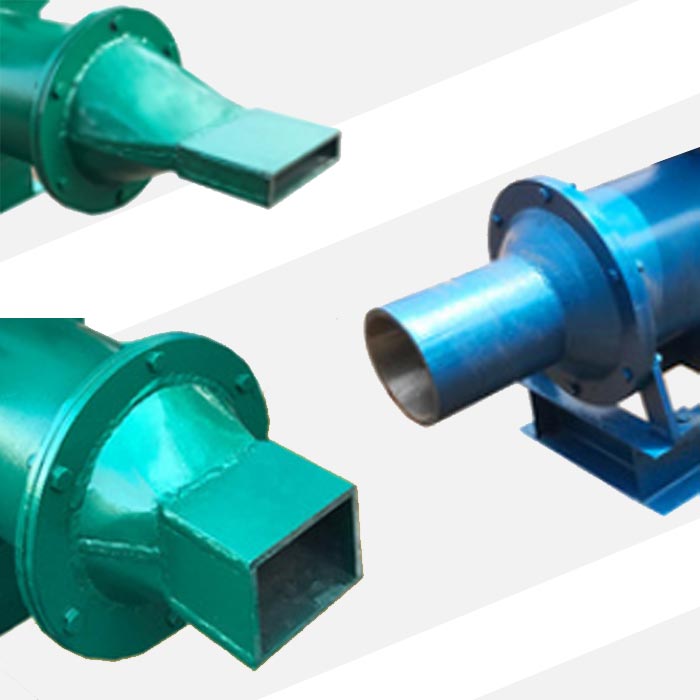

Different moulds of de-airing pug mill

The die head of the clay brick making machine can be selected according to the different needs of customers, and can also be customized upon request. Generally, customers use round, square, and flat shapes.

Parameters of clay brick extruding machine

| Model | Capacity (t/h) | Power (kw) | Size (mm) | Weight (t) |

| SL-170 | 1-2 | 7.5-11 | 1800*750*750 | o.8 |

| SL-250 | 2-4 | 18.5-22 | 2400*1000*1000 | 1.1 |

| SL-280 | 4-5 | 22 | 2400*1000*1000 | 1.15 |

| SL-300 | 6-8 | 45-55 | 4500*1500*1200 | 3 |

Product display of de-airing pug mill

Making clay bricks

According to different models, bricks of different shapes can be made by a soil brick making machine, the common size is 230*110*40mm. We can customize the size according to the needs of customers.

Making various tiles

The de-airing pug mill can not only make bricks, but also a variety of molds for making tiles, so it can also make different tiles, such as roof tiles, antique tiles, etc.

Clay brick making machine in stock

Packing and shipping of de-airing pug mill

- Customers can send questions at any time (Whatsapp, WeChat, etc.) 24 hours a day, or send an email to the mailbox, and we will arrange a sales manager to give you a satisfactory answer.

- Provide pictures that customers need during machine production, in the warehouse, and before transportation.

- Under normal circumstances, the packaging method of the machine is wooden box packaging, and the transportation method is shipping.

- In addition to wearing parts, we provide a one-year warranty for the whole soil brick making machine, 24-hour online service, and always provide spare parts at a preferential price.