Introduction of double-roller crusher

The double-roller crusher is mainly used for crushing ore. This machine has the advantages of small size, good crushing effect, low noise, simple structure, convenient maintenance, uniform size of crushed materials, sensitive overload protection, safety and reliability. It is suitable for coal, metallurgy, mining, chemical, building materials and other industries, and it is more suitable for the crushing of coal mines.

Applications of double-roller crusher

The roller crusher is suitable for crushing in cement, chemical, electric power, mining, metallurgy, building materials, refractory materials, coal mines, and other industries. Its feed size is large and the output size is adjustable. Especially in the coal industry, the use of this machine to crush raw coal can be directly crushed after iron removal, impurity removal, and no gangue removal. The crushed materials have uniform particle size and low over-crushing rate, which simplifies the coal preparation process and reduces Reduce investment and production costs.

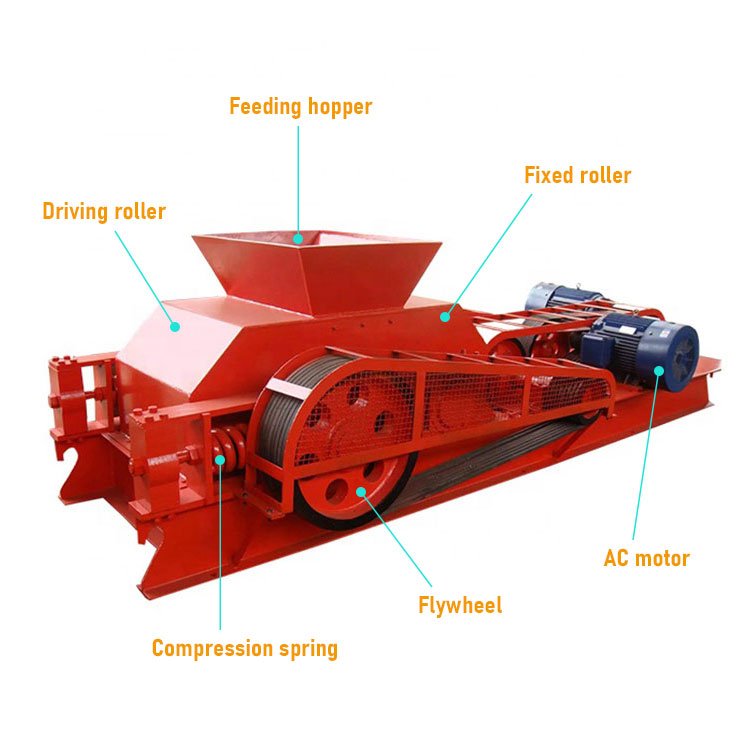

Double-roller crusher structural characteristics

Crusher performance characteristics

- The roller crusher has simple structure, small space occupation, and convenient operation and maintenance.

- The inside of the roller crusher is equipped with a dust-proof plate, which has good sealing performance, avoiding the splashing of small materials after crushing. The double roller crusher has less dust, low working noise, and greatly improves the working environment.

- The roller crusher is equipped with replaceable wear-resistant liners. The wear-resistant liners are made of domestic advanced wear-resistant materials, which have the advantages of long service life, not easy to damage, and convenient maintenance. The continuous service life can reach more than one year. When the wear is severe, the cover can be replaced.

- The roller crusher is equipped with a safety protection device. When an accidental metal iron piece enters the crushing chamber, the protection device will act, and the iron piece leakage equipment will operate normally.

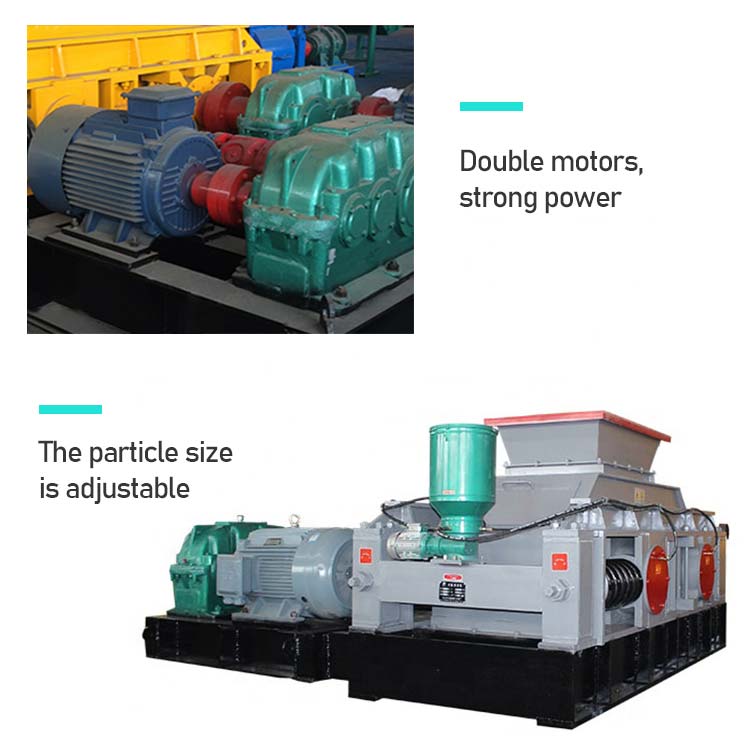

- The roller crusher has high efficiency and energy saving, high crushing efficiency, and adjustable discharge particle size.

Parameters of double-roller crusher

The following modesl are the common model of the double roller crushing machine, if you are confused to choose the machine model, you can consult us or leave a message on our website, and we will give you some advice according to your demand.

| Model | Feeding size (mm) | Output size(mm) | Capacity(t/h) | Motor power(kw) | Weight(t) | Overall Dimension(mm) |

| 2PG400*250 | <35 | <2-8 | 2-10 | 2*5.5 | 1.5 | 2110*870*810 |

| 2PG610*400 | <65 | <2-20 | 5-20 | 2*15 | 3.9 | 3510*1420*1030 |

| 2PG750*500 | <75 | <2-25 | 10-40 | 2*18.5 | 9.5 | 4210*1630*1260 |

| 2PG800*600 | <80 | <2-25 | 12-45 | 2*22 | 10.8 | 4505-1780*1320 |

| 2PG1000*700 | <100 | <3-30 | 20-65 | 2*30 | 14.9 | 5310*2175*1595 |

| 2PG1200*800 | <120 | <3-35 | 35-80 | 2*37 | 25.5 | 6290*2270*1870 |

| 2PG1500*800 | <130 | <3-45 | 50-120 | 2*75 | 33.7 | 7460*2410*2290 |

| 2PG1600*1000 | <150 | <3-50 | 60-140 | 2*90 | 42 | 8220*2680*2475 |

Recommended equipment for roller crusher

A vacuum mud machine is specially used to make bricks and tiles machine, the application of this machine can save time and effort, and greatly improve production efficiency. Some clay is hard, you can also use the crusher to crush it first, in the brick machine. After the vacuum mud machine extrusion, the air is eliminated more thoroughly, the mud is more evenly organized, and the texture of the bricks made is more uniform and harder.