The manual clay brick machine is a new type of small brick making machine, which uses waste soil, sediment, etc. that is not suitable for farming. Different from de-airing pug mill The device is used by human power, so it is also called a hand press soil brick machine. The finished bricks do not need to be baked, which can save a lot of fuel and protect the environment. If you are interested in the newest machine, welcome to consult us.

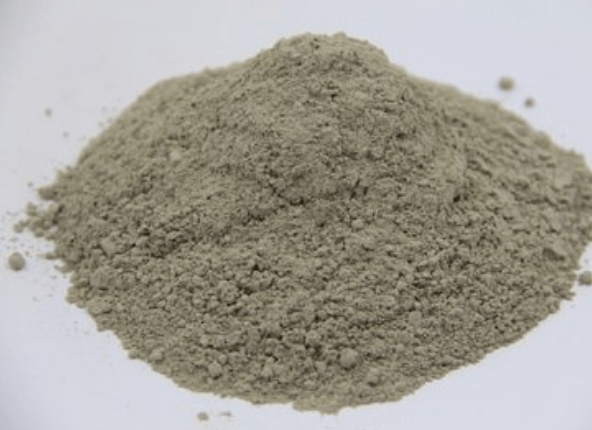

Raw material of clay brick machine

The raw materials suitable for the manual clay brick machine are usually soil, silt, cement, etc. which are not suitable for farming. As long as they have a certain viscosity and add a certain proportion of water, they can be pressed into regular-shaped bricks.

Features of manual clay brick machine

- The manual clay brick machine is small in size and easy to move, and the brick making machine has a long service life and is easy to operate. Customers can operate it after simple training.

- The finished bricks do not need to be baked and can be used directly. This saves a lot of fuel, reduces exhaust emissions, and protects the environment.

- The product has a fast forming speed, high product density, and high hardness, and the finished brick can stand on the brick.

- The hand-press soil brick maker is affordable and has a long service life. It is very suitable for customers with a low budget. The brick making machine is also the best choice for small factories.

Applications of hand press soil brick maker

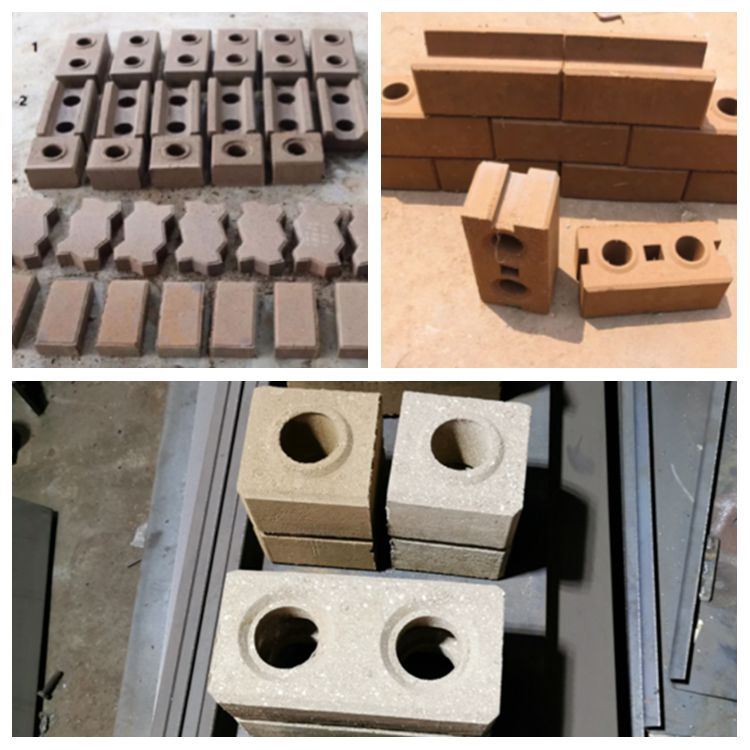

The small brick machine can produce various products by changing the mold. Such as building blocks, colored pavement bricks, lawn bricks, small concrete hollow blocks, porous bricks, garden bricks, wall blocks, etc.

Manual clay brick machine display

Our clay brick making machines are in sufficient stock, and customers are welcome to buy at any time. We provide different models and molds for customers to choose from. Welcome to consult.

Sales service of hand press brick maker

- After receiving your inquiry, our sales manager will contact you as soon as possible to understand your needs, introduce the brick making machine to you in detail, and send machine pictures and videos.

- Our factory will precisely produce equipment, accompany customers to complete machine acceptance, and assist in compiling installation plans and detailed procedures.

- If the customer encounters problems during installation or use, our company can provide online video guidance, or send technicians to the customer’s site to guide the installation of equipment, debug the normal production of the charcoal production line, and train operators to use and maintain.