The clay roof tile production line is a machine used to produce tiles. The raw material used in the production is mainly clay. The main production steps are clay crushing, mixing and molding, and drying. It can be used to produce various shapes of tiles, and it can also be used to produce clay bricks. And various patterns can be engraved to achieve beautiful effects.

What kind of clay is needed to produce tiles?

The main raw materials used in the production of clay tiles, raw clay tiles have relatively high requirements for clay, and cannot have too many impurities. The plasticity of the clay is high. Generally, too many impurities need to use a filter and remove impurities in the clay, especially some small stones.

Can clay tiles be customized in patterns and shapes?

Some clay bricks are rectangular without any patterns, and some clay tiles have various shapes, and there are patterns of He Nudu, which play a good decorative role in architecture. These can all be produced by production lines.

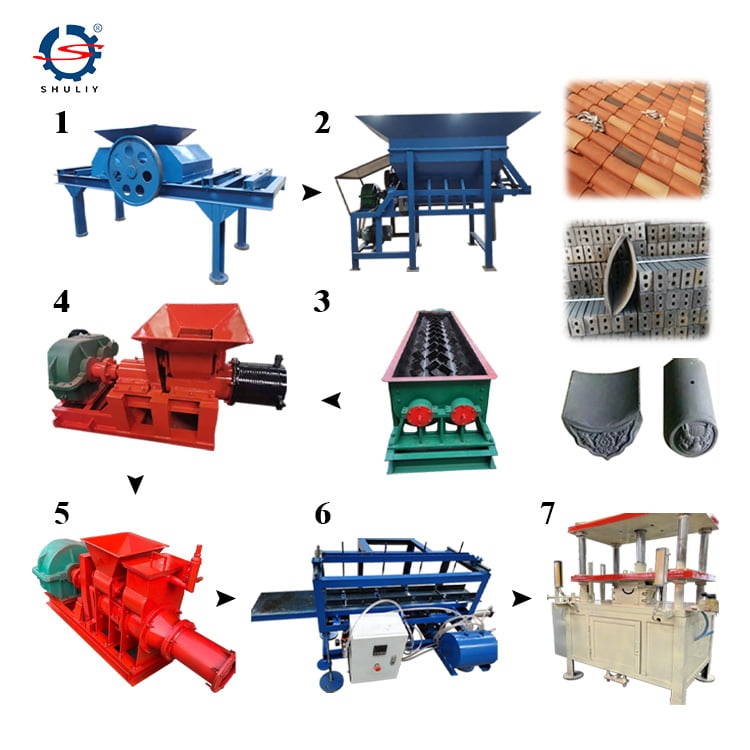

Machines included in the clay roof tile production line

Crusher—–feeder—–mixer—stone removing machine—forming machine—tile cutting machine—pattern-making machine. Through the production of several machines, the clay can be changed. For bricks and tiles.

Clay crusher

A crusher is a machine used to crush the whole piece of clay. This is the first step in the production of clay tiles, after crushing, The production raw materials are more uniform, and in addition, it also plays a role in removing impurities. The machine has low noise and high efficiency.

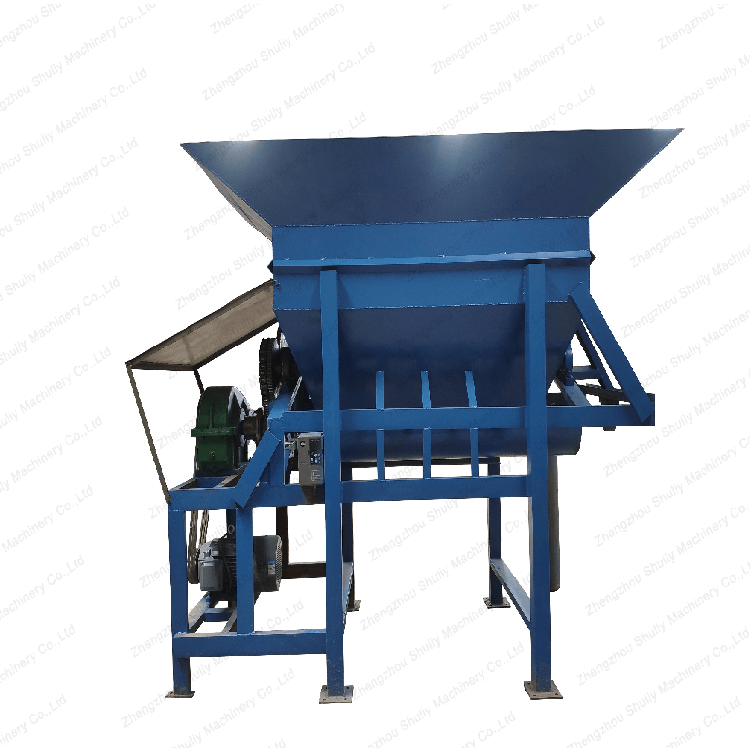

Clay feeder

After the clay is crushed, it can be put into the feeder. The function of the feeder is to evenly and slowly flow the raw materials into the next machine, which is a necessary machine for fully automated production.

Clay blender

The mixer is a machine used to mix and mix raw materials. If you want to add different materials, you can add the machine at the same time, and then mix it through the machine to achieve a uniform effect.

Stone remover

A stone remover is a machine used to remove impurities in the clay, especially if the machine is more stone or there are more impurities in the local clay, you can add this machine to remove the impurities in the raw material. It is worth noting that the stone remover should regularly clean the impurities filtered out by the machine so that the machine can improve its working efficiency of the machine. The clay roof tile production line can choose whether to need a stone removal machine according to the local clay situation

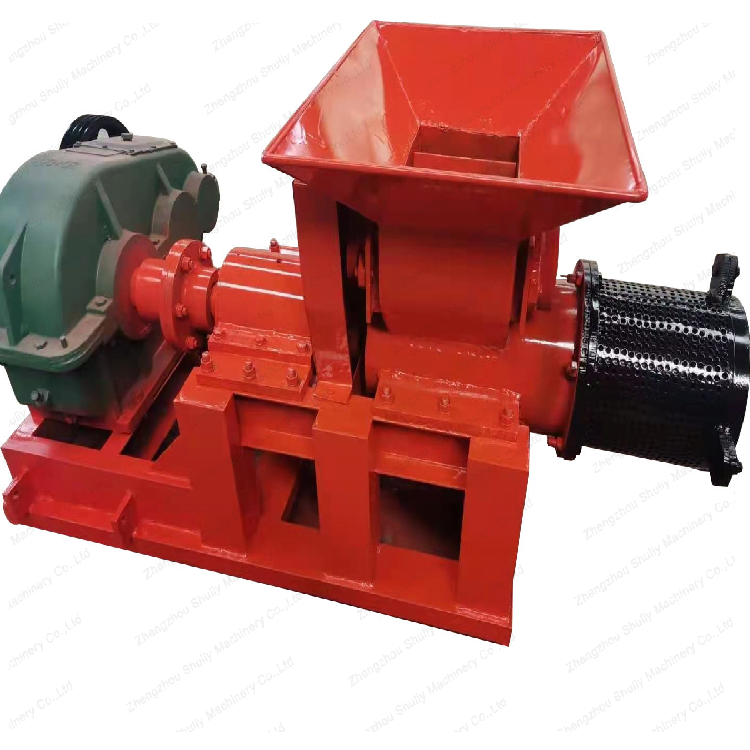

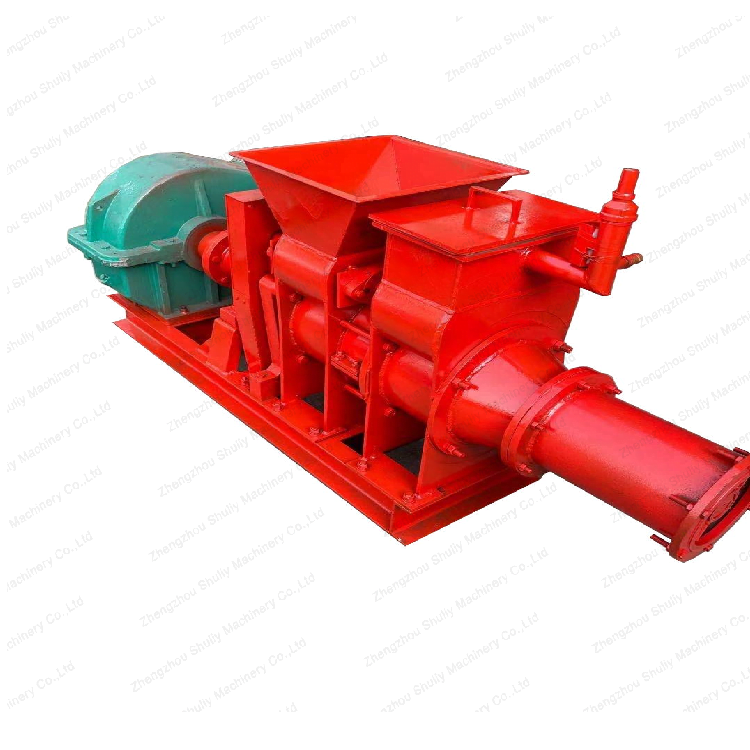

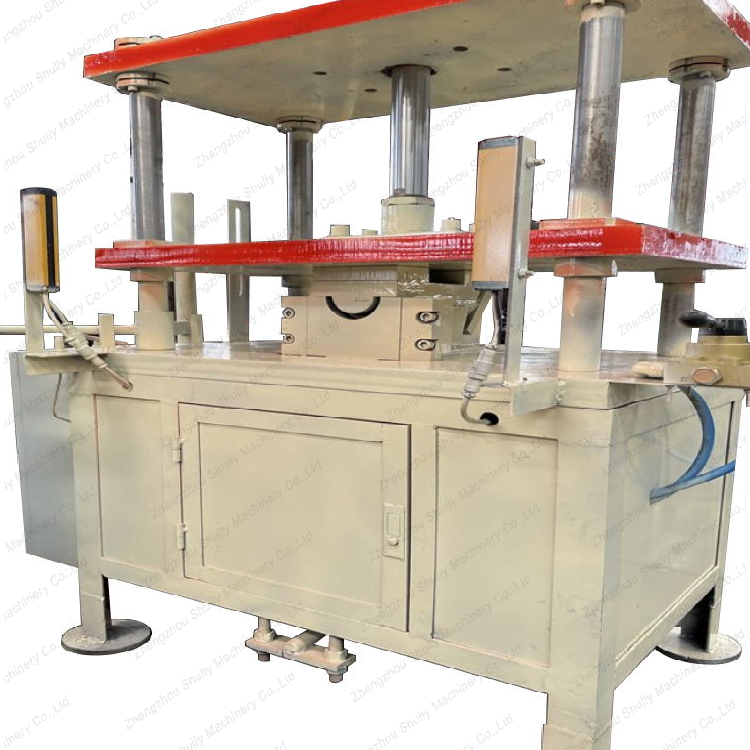

Clay tile forming machine

A molding machine is a machine used to make clay into a specific shape, such as a semicircle, rectangle, and other shapes. The machine uses a mold to make clay into different shapes.

Tile cutter

The tile-cutting machine is used to divide the formed tiles to form tiles of the same size. There are two types of tile cutters: manual tile cutter and automatic tile cutter. Our production line uses a fully automatic tile-cutting machine.

Tile press

The appearance of some tiles is very beautiful, there are various patterns, the different patterns on the tiles are made by the tile press. The machine engraves patterns on the cut tiles to form tiles with different patterns. It is decorative.

Video of clay roof tile production line

Global cases of clay roof tile production line

Shuliy clay roof tile making machines have been exported to the USA recently. The customer chose one roof tile making machine, one tile cutter, tile molds, and other auxiliary equipment. We provided customized services for them and designed molds of a special shape. Now the machines have been shipped to the USA, we will update the feedback on the machines.

If you are interested in the clay roof tiles-making machine, feel free to consult us anytime and leave your messages on our website.