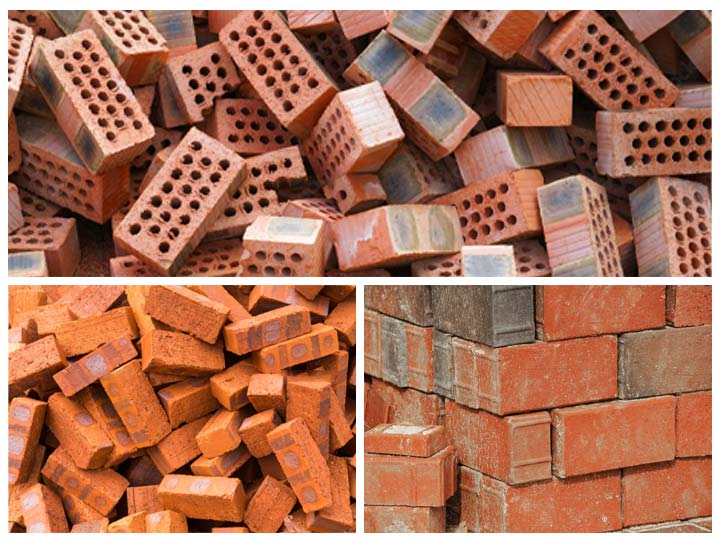

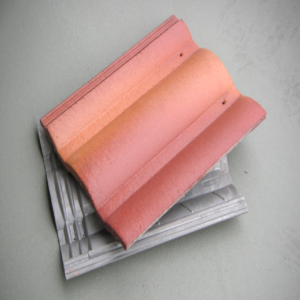

Clay bricks are used in large quantities in many countries in Africa, and these bricks are used to build houses, make roof tiles, etc. Although the amount is large, but the price is low, so it is popular. Although clay bricks are common, the production process requires some techniques and attention.

Clay bricks need to go through a series of processes such as raw material picking, crushing, mixing, high-pressure molding, cutting and other production, but because of the impurities in raw materials, the production is not well controlled. Today we will introduce some points to improve the quality of clay bricks.

First of all, from the raw materials, you can not directly put the clay into the molding machine, in the raw materials, usually mixed with a lot of stones, metal, plastic and other substances, in addition there are clay clumping phenomenon is serious, directly put into the machine will damage the machine. The raw materials should be sieved once to remove the debris, and then put into the mixer to mix, while adding some water and binder, so that the raw materials processed are very fine, and the quality of the clay bricks produced can be guaranteed.

Clay brick composition of raw materials in the composition of the particles of clay bricks have a great relationship with the strength and density of clay bricks. The raw material particles should be large, medium and small particles with reasonable ratio to improve the quality of clay bricks. Clay brick particles in the crushing, must ensure that the granule formula. Particle distribution is reasonable, and mixing time can not be too short. Only the particle grade with reasonable, raw material impurities less, a mixing time of 12 minutes or more, the production of clay bricks will be neat edges and corners, the surface is smooth.

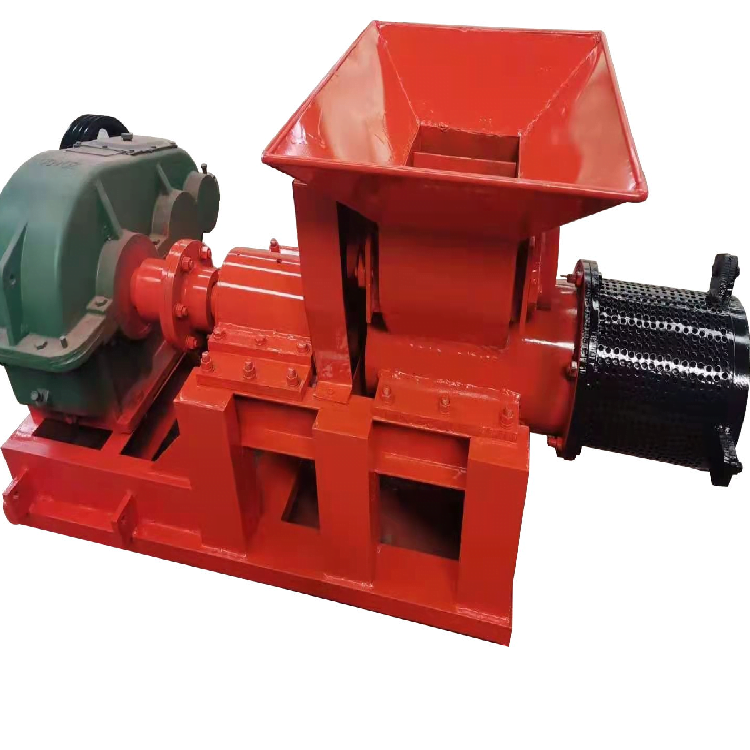

Clay brick to improve product quality, from the source of raw materials is very important, but high-pressure molding is also the key. High-pressure molding of clay bricks has high density and strength. We recommend the use of a vacuum red brick clay-making machine. The vacuum pump on the machine can effectively eliminate air and improve the density and hardness of the brick. The bricks made with the vacuum brick machine do not need to be fired and can be used after drying naturally for a period of time, and the indicators of clay bricks are only guaranteed.

To improve the quality of clay bricks, we need to pay attention to a series of details from raw material screening, to crushing and molding to ensure the quality of clay bricks. Shuliy Machinery provides high-quality red clay brick making machine, mixers, and can match a complete brick production line for customers, welcome to consult at any time.